RJD Project Workshop

DESIGN | ADAPT | IMPROVE

Looking to improve productivity whilst reducing operator risk? The RJD PROJECT WORKSHOP will collaborate with your production team to share skills & experience to develop a much-improved workflow.

Looking to improve productivity whilst reducing operator risk? The RJD PROJECT WORKSHOP will collaborate with your production team to share skills & experience to develop a much-improved workflow.

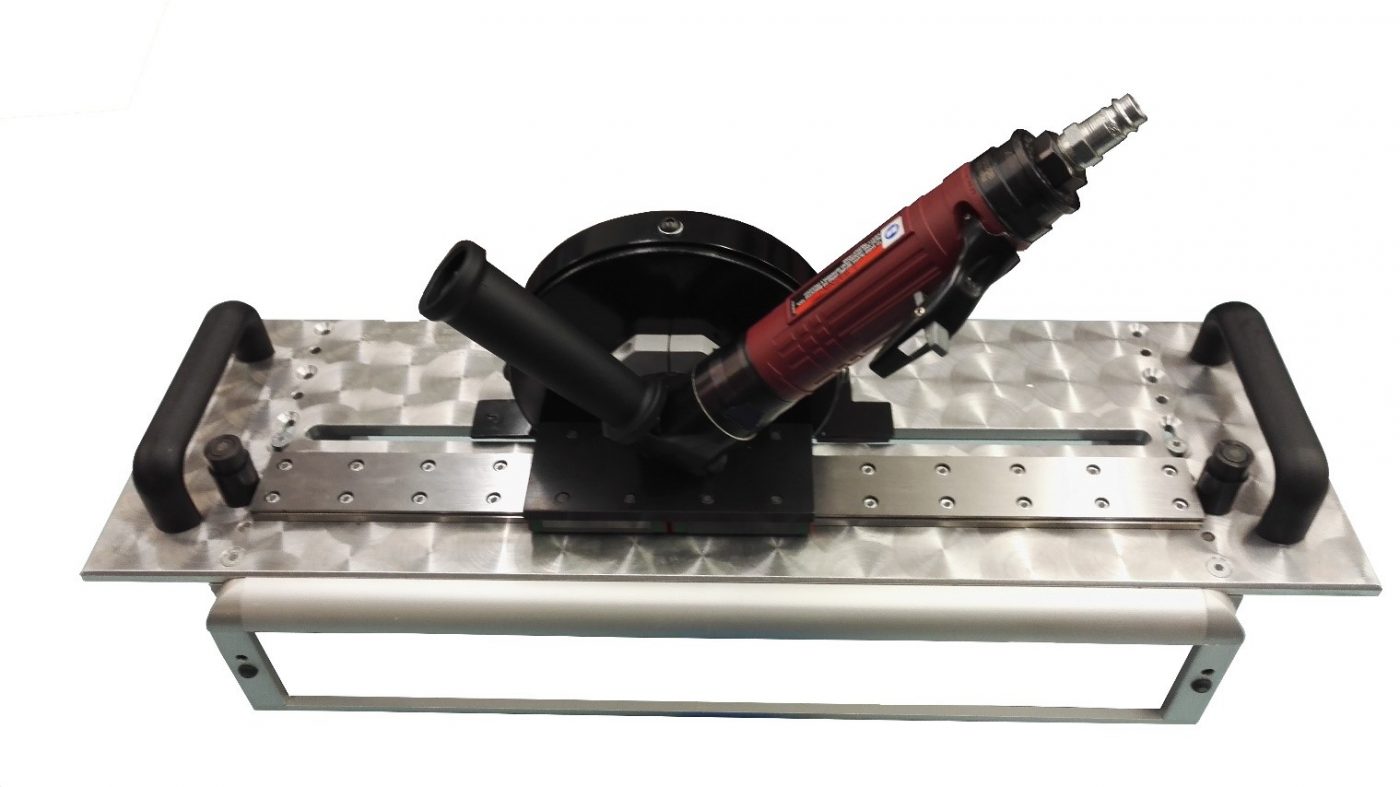

When AIRCRAFT WINGS are being manufactured a number of high resistant carry lugs are machined onto them so they can be moved and positioned using lifting gear. Once assembly is complete these lugs are redundant and need to be removed. Previously this was done by hand. Not only is this a lengthy process, there is a high risk of damaging the wing

The RJD Lug Removal Tool, designed and manufactured to:

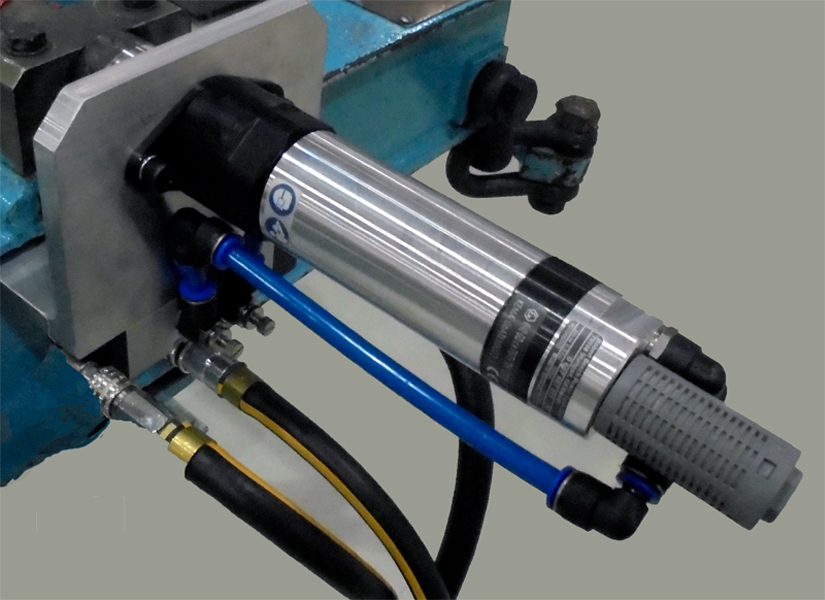

Aircraft manufacturing demands high PRECISION drilling, often in difficult or restricted spaces. Our client required a high precision drilling and back spot facing tool.

The RJD SCREW FEED DRILL features:

We were approached to help improve the operating of a positioning jig on the Hawk Jet Line.

Positioning Jig drive & pendent control features:

At RJD our aim is to focus resources on total quality. Not just a plan to limit defects and errors to an acceptable level, but a complete commitment and participation from both our employees and suppliers to continually improve.

Institution of Occupational Safety and Health

The Contractors Health and Safety Assessment Scheme